By leveraging OMRON’s industry expertise and proven educational track record, we provide content that aligns with on-site realities.

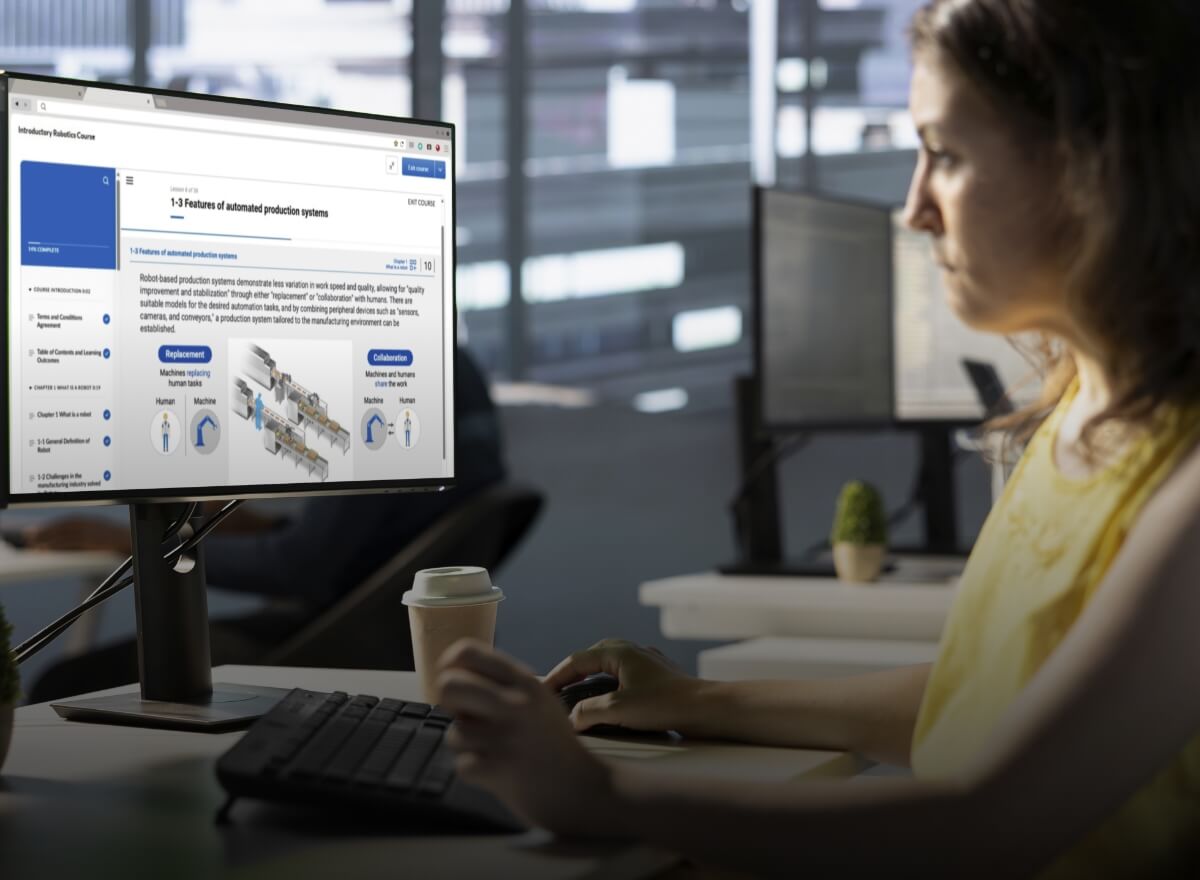

On-demand format enables repeated learning for full understanding, anytime, anywhere.

A wide range of courses is available, from fundamental principles to practical applications. Here are some examples.

Course Outline

Learning Outcome

Course Contents

Contents are subject to change without notice.

Course Outline

Learning Outcome

Course Contents

Contents are subject to change without notice.

Course Outline

Learning Outcome

Course Contents

Contents are subject to change without notice.

We filled the missing pieces in our onboarding process and achieved efficient training outsourcing.

Material Handling Systems Manufacturing

/ Technical Training Division

[Training Planner]

The on-demand format allowed me to balance work and learning in my spare moments.

Electronics Manufacturing

/ Manufacturing Division

[Participant]

I used to struggle to see the big picture of the factory organization, so Introductory Production Course was especially helpful.

Technical Staffing Services

/ Hardware Engineer

[Participant]

Find out how we turn customer challenges into effective learning solutions with our tailored curriculum.

Customer Challenges

To improve understanding because external machinery safety courses have not reached the expected level of comprehension.

Curriculum Aim

Repeated on-demand learning of core principles in a systematic format leads to better comprehension during external courses and practical sessions.

OMRON has consolidated the unique insights gained from its global IA business and the educational expertise developed worldwide into on-demand learning.

01. Learner-Focused Materials

Globally unified design for readability and ease of understanding. Subtitles available for learning in environments without sound.

02. Global Standard Learning Platform

Our platform enables digital certificate, progress and proficiency visualization, and multi-device access.

03. Synergy with Face-to-Face Training

The combination of on-demand and face-to-face training in about 800 courses worldwide ensures a synergistic effect for deeper learning and solid knowledge retention.

04. Global Achievements in Training

A delivery network established across 150 locations in 40 countries/regions, offering a globally standardized curriculum for learners worldwide.

If you have questions about the service overview or would like to arrange a meeting, please feel free to contact your nearest national office.

If you have any opinions or requests for this website, please contact us here.

Please note that the contents of your inquiry and your personal information may be shared with OMRON Group companies.

For more information, please refer to our Privacy Policy.